Greens Creek

Admiralty Island, Alaska

As the largest silver mine in the United States, the team at Hecla Greens Creek has demonstrated that its safety record and environmental stewardship are among the best in the world.

As the largest silver mine in the United States, the team at Hecla Greens Creek has demonstrated that its safety record and environmental stewardship are among the best in the world.

Mine Type

Ownership

Silver

Gold

Lead

Zinc

***All metals reflect 2024 production

At our Greens Creek mine, we established the Greens Creek Community Advisory Committee (CAG), a collaborative effort with our local stakeholders to ensure that input from the community is considered in the environmental and social aspects of the mine’s planning and operations. In 2024, the group included a representative of the Angoon community and a Tribal Liaison from the Alaska Broadband Office, the Mayor of Juneau, the Executive Director of the Greater Juneau Chamber of Commerce, the Chancellor and Dean of Career Education, University of Alaska Southeast (UAS), an Energy educator from Sustainable Southeast Partnership, the Juneau Economic Development Council Executive Director, and a U.S. Forest Service Partnership Liaison.

The Greens Creek Mine has been a proud member of the Juneau community for more than 35 years. Today, we are the region’s largest private employer and its largest taxpayer, providing approximately 510 direct jobs and just over 450 indirect jobs statewide.

The salaries and taxes we pay contribute to making Juneau a better place to live – from enabling our employees to own good homes, to helping our local government provide essential services. These expenditures radiate throughout the community – from employees taking their families to locally owned restaurants to supporting seemingly unrelated jobs within local governments and businesses.

In 2024, Hecla had a significant economic impact in the local community of more than $266 million, including over $86 million in wages, $27 million in taxes and fees, and $151 million in purchases from vendors. Our purchase of surplus hydropower has also helped provide Juneau residents with more than $96 million in reduced electricity rates since 2009. Greens Creek is also the largest provider of student aid at the University of Alaska Southeast (UAS) contributing more than $1.8 million dollars since 2011.

In addition, the men and women of Hecla Greens Creek are empowered to leverage the resources of our company to benefit the community – from making charitable contributions to local schools and nonprofit organizations, to rallying participation in volunteerism.

We annually support about 60 local and youth groups, art and education programs. We also proactively provide programs, marketing and information to help guide local residents into great careers at Hecla Greens Creek.

Safety is all about people. From engineering to behavior on the job, people are responsible for designing our mining process and safety protocols, and people are responsible for performing our work in a manner that best protects both personnel and the environment.

We believe in hiring the best people, providing them with the best training and the best supervisors, and empowering every one of our people to be personally responsible for safety – even if that means stopping a job or speaking up to a supervisor. At Hecla Greens Creek, we’re proud of our environmental and human safety record – and we work very hard to make safety our No. 1 priority.

Part of being Miner Strong means working hard while also protecting our teammates and environment.

Each Hecla employee and contractor is responsible for incorporating this policy into their daily planning and work activities to achieve this commitment. Here’s a video on Hecla’s commitment to safety

Under our culture of safety, we are always seeking ways to operate more safely, more efficiently and more effectively. This includes everyone from our senior engineers to our newest employee. We encourage everyone employed at Hecla Greens Creek to take responsibility for his or her own actions. Our employees actively think about how to do their jobs better, make suggestions to supervisors, and speak up when necessary. We encourage action any time a coworker is acting in a manner that is unsafe, disrespectful or abusive to anyone at our mine. We are a team, and a team looks out for each other.

Energy conservation is not just good for our environment, it’s good business. At Greens Creek, 84% of our electricity is sourced from the grid, of which 100% is renewable hydropower. In Alaska, Hecla purchases hydroelectricity from the Juneau-area utility company, Alaska Electric Light and Power (AEL&P) to power the Greens Creek mine. As a result, we thus avoided the use of over 70 million gallons of diesel fuel. Our purchase of surplus hydropower has also helped provide Juneau residents with over $96 million in reduced electricity rates since 2009.

Hecla Greens Creek Mine was an early adopter of the dry-stack method of tailings management. In this method, tailings are filter-pressed to a low moisture content and then trucked and placed into a “dry stack” that does not dam or impound water. This method minimizes the tailings surface footprint, lessening the impact on nearby wildlife habitat, while also eliminating the storage of free-standing water with tailings and significantly reducing the consequences of failure. We also seek to reuse a high percentage of tailings as underground backfill rather than store them on the surface, which increases stability, improves safety, and reduces surface storage requirements and surface disturbance.

Hecla Greens Creek strives to reduce waste output on all fronts. We continuously explore the environmentally responsible use of resources, products and materials. We have developed active programs for reuse, recycling and recovery of all non-mineral wastes. An important element of our waste program is employee training. All mines have dedicated trainers to ensure everyone is trained appropriately for their tasks. Mineral waste (rock from mining development and mill tailings) remains on site and is utilized as much as possible for backfill in our underground mine and construction in and around our operation. In 2024, Greens Creek reused 46% of tailings as backfill instead of going to the dry stack.

Hecla is also studying the economic potential of recovering and re-processing critical minerals from mine tailings. Minerals in our tailings at Greens Creek include silver, gold, zinc, lead, copper, nickel, arsenic, barium, bismuth, cadmium, chromium, gallium, germanium, manganese, and vanadium.

Hecla Greens Creek is required to return the mine site to a natural state after mining operations have ceased years from now. This includes removing structures, regrading and seeding the land, protecting and monitoring the tailings-storage facility and monitoring water quality. Over time, native trees and plants should reclaim the area. Some material will be buried in on-site landfill trenches that will be covered with soil and reclaimed, as required by regulatory agencies.

To guarantee this reclamation occurs, we have posted bonds totaling $92.17 million including $16 million that would establish a trust fund to cover long term water monitoring and treatment. These bonds are collectively held by the United States Forest Service and the State of Alaska through a MOU.

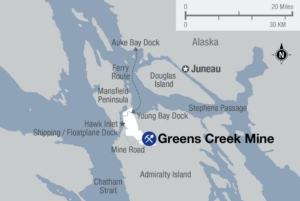

Virtually everything we do prioritizes the care and protection of this exceptional part of Alaska. We are located on Admiralty Island about 18 miles southwest of Juneau and 40 miles north of Angoon.

The Greens Creek facility in Alaska is allowed to operate inside a federally protected national monument. Most of Admiralty Island is a federally protected wilderness area administered by the Tongass National Forest. More than 955,000 acres (3,860 km2) of it have been designated as a national monument. Greens Creek sits inside the national monument on the northwest end of the island, but outside the 936,649-acre Kootznoowoo Wilderness area.

Environmental stewardship starts with safety, and safety is reliant on the quality, training, and dedication of our people. Hecla Greens Creek prioritizes finding the best people and arming them with thorough training and quality leadership. Our goal is to ensure Hecla employees always put safety first in everything they do every day. This is important for the safety of our mine, our environment and our employees, and it means we must maintain a dedication to both big-picture engineering and everyday worksite behaviors.

Hecla Greens Creek meets the very stringent state and federal standards for air and water quality. In addition, we continually work to devise ways to conserve water through efficient operations, engineering and training. Our regulators monitor the mine through a robust program of sampling, quality analysis and audits. We discharge water into Hawk Inlet that is treated to the state’s stringent water quality standards. This discharge is regulated through state and federal permits, and ongoing monitoring finds it is well within the permitting thresholds.

Hecla also collaborates with federal and state agencies to fulfill our commitment to rigorous biomonitoring. At Greens Creek, we work with the Alaska Department of Fish and Game to complete annual freshwater surveys of salmonids, their feed, and their habitat. In 2024, new monitoring points were established in accordance with the November 2024 Record of Decision, reinforcing the commitment to maintaining rigorous and ongoing biomonitoring efforts.

Hecla uses and develops new technologies to maximize the safety of our people and our environment, to improve efficiency, to reduce our footprint, to limit our impact and to achieve our primary goal: responsible mining. We consistently adopt technological advances in mining across the entire project – from communications to mining tools to personal safety gear.

We use applications such as high-speed wireless data transfer for underground monitoring, communication, data assessment and remote control. We are advancing tele-remote and battery-powered load, haul and dump equipment. This both reduces ventilation requirements and improves worker safety and lower emissions.

Our operations have upgraded underground ventilation, implemented cleaner engine technology and exhaust filtration, introduced enclosed and environmentally controlled cabs, and required protective equipment in high-exposure tasks and work areas.

Reducing lead exposure in the mill operations is also a priority. Annual blood tests measure employee exposure, which is minimized through personal hygiene training and the use of state-of-the-art respirators.

By mounting variable-frequency drives to our underground fans, we’re able to operate those fans at the right speeds at the right time, which in turn lowers our power consumption. Just one of these drives can save about $23,000 over the course of a single year. In addition, these technologies are lowering our environmental footprint – reducing greenhouse gas emissions, potentially reducing the volume of non-ore material brought to the surface and improving water management at our mines.

Email: [email protected]

Phone: 907-600-7737

Mailing: Hecla Greens Creek

PO Box 32199

Juneau, AK 99803

The Greens Creek orebody contains silver, zinc, gold and lead, and lies within the Admiralty Island National Monument. We are the only mine congressionally designated to operate in a national monument. The Greens Creek property includes 17 patented lode claims and one patented mill site claim, in addition to property leased from the U.S. Forest Service. Greens Creek also has title to mineral rights on approximately 7,500 acres of federal land adjacent to the properties. Total property package encompasses 23-square miles. The entire project is accessed by boat and served by 13 miles of road.

The Hecla Greens Creek mine holds current proven and probable silver reserves of 103,711 million ounces, 865 ounces of proven and probable gold reserves, as well as 240,670 tons of lead and 646,010 tons of zinc in proven and probable reserves.

Major facilities include the subsurface mine, an ore concentrating mill, a dry stacked tailings facility, a ship-loading facility, camp facilities and a ferry dock.

The mine began production in 1989 and today operates 24-hours a day, 365 days a year.

To learn more about Hecla, look here. To apply for current job openings at Greens Creek or any of our other operations, apply here.

The mine holds current proven and probable reserves of 105.2 million ounces for silver, 880 thousand ounces of gold, 250.6 tons of lead and 658.7 tons of zinc. Based on these reserves, Greens Creek has a 14-year mine life. Measured and Indicated resources contain 111.5 million ounces of silver, 239.2 thousand tons of lead and 643.9 thousand tons of zinc; Inferred resources contain 25.9 million ounces of silver, 55.9 thousand tons of lead, and 133.3 thousand tons of zinc.

| Tons(000) | Silver(oz/ton) | Gold(oz/ton) | Lead(%) | Zinc(%) | Silver(000 oz) | Gold(000 oz) | Lead(Tons) | Zinc(Tons) | |

|---|---|---|---|---|---|---|---|---|---|

|

9 |

7.6

|

0.07 |

2.4 |

6.5 |

70 |

1 |

220

|

600 | |

|

10,438

|

9.9 |

0.08 |

2.3 |

6.2 |

103,641

|

864 |

240,450

|

645,410

| |

|

10,447

|

9.9

|

0.08 |

2.3 |

6.2 |

103,711 |

865 |

240,670 |

646,010

| |

|

– |

– |

– |

– |

– |

– |

– |

– |

– | |

|

7,619 |

14.1 |

0.10 |

3.0 |

8.0 |

107,226 |

760 |

227,360 |

607,600

| |

|

7,619

|

14.1 |

0.10 |

3.0 |

8.0 |

107,226 |

760 |

227,360 |

607,600

| |

|

1,878

|

13.4 |

0.08 |

2.9 |

6.9 |

25,106 |

151

|

54,010 |

130,120 |

Totals may not represent the sum of parts due to rounding.

(2) Mineral reserves are based on $22/oz silver, $1,900/oz gold, $0.90/lb lead, $1.15/lb zinc, unless otherwise stated. All Mineral Reserves are reported in-situ with estimates of mining dilution and mining loss.

(3) The reserve NSR cut-off values for Greens Creek is $230/ton for all zones; metallurgical recoveries (actual 2024): 79% for silver, 72% for gold, 81% for lead, and 89% for zinc.

Note: All estimates are in-situ except for the proven reserves at Greens Creek which are in surface stockpiles. Mineral resources are exclusive of reserves.

(12) Mineral resources are based on $2,000/oz gold, $24/oz silver, $1.15/lb lead, $1.35/lb zinc and $4/lb copper, unless otherwise stated.

(13) The resource NSR cut-off values for Greens Creek is $230/ton for all zones; metallurgical recoveries (actual 2024): 79% for silver, 72% for gold, 81% for lead, and 89% for zinc.

(years ended December 31)

|

2020 |

2021 |

2022 |

2023

|

2024

| |

|---|---|---|---|---|---|

|

Silver (ounces) |

10,494,726 |

9,243,664 | 9,741,935 | 9,731,752 |

8.480,877

|

|

Gold (ounces) |

48,491 |

46,088 | 48,216 | 60,896 |

55,275

|

|

Lead (tons) | 21,400 |

19,873 | 19,480 | 19,578 |

18,320

|

|

Zinc (tons) | 56,814 |

53,648 | 52,312 | 51,496 |

51,288

|

Greens Creek is 30% of the exploration budget.

The Greens Creek deposit is a polymetallic, stratiform, massive sulfide deposit. The host rock consists of predominantly marine sedimentary and mafic to ultramafic volcanic and plutonic rocks, which have been subjected to multiple periods of deformation. These deformational episodes have imposed multiple folding of the orebodies to create a complex geometry. Mineralization occurs discontinuously along the contact between a structural hanging wall of quartz mica carbonate phyllites, and a structural footwall of graphitic and calcareous argillite.

Ore lithologies fall into two broad groups: massive ores with over 50% sulfides and white ores with less than 50% sulfides. The massive ores are further subdivided as either base-metal or pyrite dominant. Massive ores vary greatly in precious-metal grade from uneconomic to bonanza Au (>.5 opt) and Ag (>100 opt). White ores are subdivided into three groups by the dominant gangue mineralogy: white carbonate, white siliceous, and white baritic ore. These ores tend to be base-metal poor and precious-metal rich. Important minerals include pyrite, sphalerite, galena, and tetrahedrite/tennanite.

Greens Creek is an underground mine that produces approximately 2,300 tons of ore per day. The primary mining methods are cut and fill and longhole stoping.

The Greens Creek unit has historically been powered completely by diesel generators located on site. However, since 2006, Hecla has purchased excess hydroelectric power from the local power company, Alaska Electric Light & Power Company (“AEL&P”). This project has reduced production costs at Greens Creek when hydroelectric power has been available. Since 2009, hydropower has provided 77% of Greens Creek’s energy needs.

There are three main phases to the mining process: development, production, and backfilling.

Development – the tunneling or accessing phase

Using plans from the geology and engineering departments, miners drive tunnels 15ft high by 15ft wide to access the various ore zones to be mined.

Production – the extraction phase

The method of extraction depends upon the geological nature of the orebody involved. Some of the smaller, more contorted orebodies are extracted using the same tunneling procedure as the development phase. In other more massive orebodies, larger scale extraction methods are used, sometimes producing voids of up to 150ft long, 25ft wide and 120ft deep.

Backfilling – the replacement phase

The voids created during the production phase are filled up with a combination of mill waste (tailings) and cement. This “backfilling” process stabilizes the production voids and allows extraction of the ore beside, above, and even below the backfilled area.

Greens Creek is a strong community partner through investment and volunteerism and is the largest private-sector employer and taxpayer in Juneau, Alaska. In 2024, Hecla had a significant economic impact in the local community of more than $266 million, including over $86 million in wages, $27 million in taxes and fees, and $151 million in purchases from vendors.